OPTICAL MEMS BY SERCALO

OPTICAL MEMS FOR FIBER OPTICS

The optical MEMS technology is based on the silicon technology that gave its name to Silicon Valley in the late 1960ies. The acronym MEMS stands for Micro Electromechanical Systems.

Optical MEMS devices are used in the fiber optic industry. They allow a photonic signal, travelling through an optical fiber at the speed of light, to be redirected, routed, or filtered functioning as an optical interface between two or more fibers. What is so complex about optical MEMS is that you must achieve total flatness on mirrors that are only one micron wide and 100 microns high. This is to avoid loss of light, first requirement in fiber optic applications.

The optical MEMS chips are the principal building block of Sercalo’s fiber optic products. Optical MEMS are produced with the high precision tools of the microelectronics industry, ideally suited for parallel manufacturing of hundreds of chips on a single wafer. Optical MEMS offer unique combinations of optics, electronics, and micro mechanics, achieving precise control of optical signals with minimal losses.

The outstanding stability of Sercalo switches over time is critical in optical Test and Measurement applications where test set up recalibration must be avoided.

THE REQUIREMENTS OF THE INDUSTRY

The first requirement of the industry is to avoid or reduce the degradation of the signal and to suffer only minimal modal loss after each reflection on the mirror. Sercalo meets this requirement with unique in house manufacturing capabilities.

The Sercalo team has achieved such a high level of quality and expertise in the field of optical MEMS by passionately focusing on the optimization of all relevant manufacturing processes for over 20 years.

There is a growing demand for fiber optic switches, and we observe an increased in interest in the Sercalo high port count optical switching solutions featured by the highly reliable and proven coaxial optical MEMS switch where size does not increase with the number of ports. Sercalo has brought to the market coaxial optical MEMS switches with port count configurations of up to 16 inputs and 16 outputs for the SCBU MxN and 1 input with up to 60 outputs for the SC1xN.

MARKET LEADER IN OPTICAL MEMS

Since 1999, Sercalo is a leading provider of fiber optic MEMS technology and optical MEMS products for applications in telecommunications as well as test and measurement. We are a very responsive engineering team, with fast decision-making and development capabilities. Typically, we complete the proof of concept of a new product in less than 9 months with a time to market below 12 months.

Our location in Switzerland fosters a unique culture and know-how in micro mechanics. Sercalo is recognized for its high quality manufacturing and development. The combination of Swiss quality with high productivity enables us to make products that can compete with the best on the market. When producing low volume optical MEMS, most of our competitors rely on an external MEMS foundry. Sercalo took the opposite path, relying on an in-house MEMS foundry that gives total control over all manufacturing processes. This policy allows us to guarantee performance and quality of the optical MEMS components.

ADVANTAGES OF SERCALO’S TECHNOLOGY

ADVANTAGES OF SERCALO’S TECHNOLOGY

Our skills span the entire production process, from in house optical MEMS chip design and qualification to wafer processing in our MEMS foundry and assembly of the final component. All products are designed, manufactured, and certified "Swiss Made".

Sercalo’s fiber optic components are market leaders thanks to their:

- Reliability

- Wide wavelength range covering the full range of the used fibers

- Solid state like repeatability

- Resistance to wear

OPTICAL MEMS TECHNOLOGY

OPTICAL MEMS TECHNOLOGY

The MEMS technology uses integrated circuit processing techniques to create precise and moveable structures on silicon substrates. MEMS are the union of microelectronics and micro machining technologies. It is MEMS technology and the design expertise in electronics driver designs that makes Sercalo's products stand out in the market. Sercalo's patented MEMS technology is based on micro mirrors fabricated in single crystal silicon.

Optical MEMS and MOEMS have had the greatest success to date in Telecom, 3D Print, LiDAR, Ophthalmology, Laser writer and Lab use.

SERCALO OPTICAL MEMS

SERCALO OPTICAL MEMS

MEMS are used in telecommunication networks at different levels such as in tunable lasers, tunable filters, optical switches, dynamic gain equalizers, attenuators.

Sercalo has an in house design expertise and manufacturing capabilities in:

- MEMS design and manufacture based on deep reactive ion etching

- Electronics design

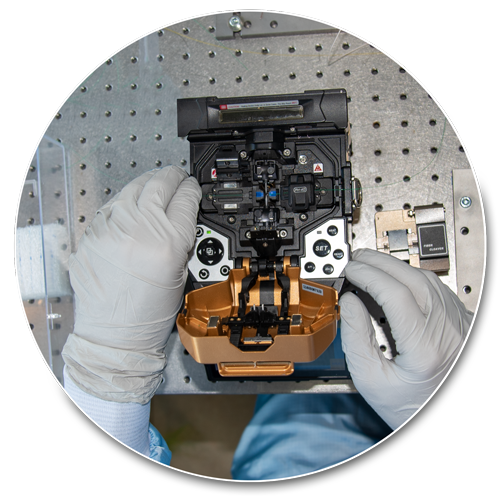

- Precision MEMS micro assembly

- Fiber Optic MEMS packaging

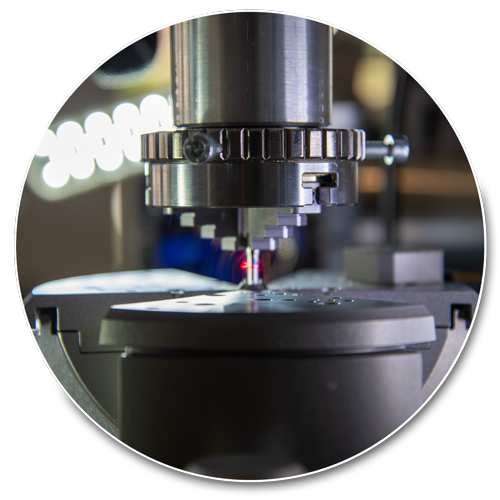

- Test and Measurement of critical optical and mechanical parameters

SERCALO FACILITY

SERCALO FACILITY

Sercalo’s products are highly reliable due to mature MEMS technology. There is no sticking, no friction, no wear out, nor fatigue. This is why a MEMS switch can operate billions of cycles, maintaining the same output results.

Sercalo qualifies its fiber optic components according to the Telcordia 1221 standard (mechanical shocks, vibration, high number of thermal cycles, damp heat etc.)

STEP BY STEP

| Wet Processing | Dry Processing | Assembly Line | Qualification |

|---|---|---|---|

| Photolithography | DRIE Etching | Wafer Probing | Mechanical shock |

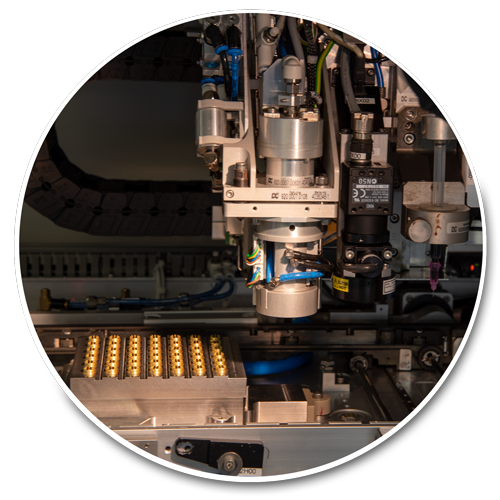

| Wet Etching | O2 Plasma cleaning | Automated Pick place | Vibration |

| HF Vapor release | PVD | Wire Bonding | Thermal cycles |

| Dry Wet oxidation | Pigtail assembly | Damp heat | |

| Package sealing | |||

| Laser Welding | |||

| Fiber optic Test and Measurement |