MEMS MIRRORS

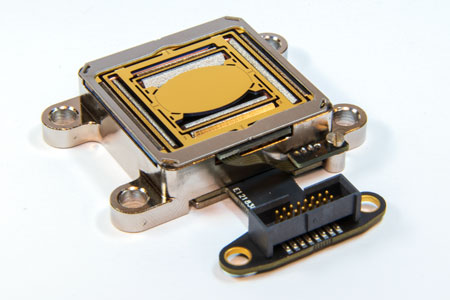

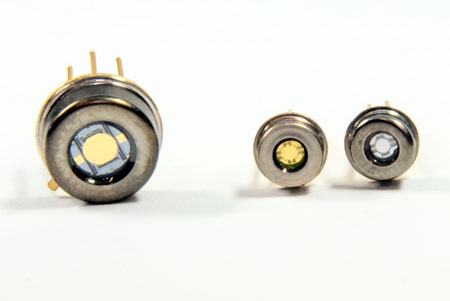

Sercalo produces MEMS Mirrors based on different technologies:

- Electrostatic driven MEMS mirrors are used in applications where a high pointing stability is required. The electrostatic drive has better DC performance and is the solution of choice for advanced fiber optic light processing such as in MEMS variable optical attenuators, fiber optic switches and tunable optical filters. Mirror diameters range from 0.8 mm up to 2.5 x 2.0 mm.

- The Magnetic MEMS micro-mirrors offer larger diameters and are best suited in applications requiring DC pointing together with dynamic scanning. Magnetic 1D and 2D micro-mirrors have a linear current angle response.

Sercalo's engineering team designs, manufactures and tests each component, assuring in this way the high quality and reliability that characterize all optical MEMS products.

| Mirrrors Family | Magnetic | Electrostatic | Dual Axes | Size [mm] | Tilt angle [°] | Resonance Frequency [Hz] | Package |

|---|---|---|---|---|---|---|---|

| MM2536-2 | X | - | X | 2.5x3.6 | Max= ±5 | X= 390 / Y= 240 | - |

| MM160110-2 | X | - | X | 16.0 x 11.0 | Max= ±1.5 | X= 350 / Y= 200 | - |

| TM10 | - | X | X | ∅1.0 | X= ±3.5 / Y= ±3.5 | X= 700 / Y= 700 | TO46 |

| TM2520 | - | X | X | 2.5x2.0 | X= ±4.5 / Y= ±2.5 | X= 170 / Y= 360 | TO5 |

About our MEMS mirrors

Our MEMS (microelectromechanical systems) mirrors are miniature mirrors that use microelectromechanical technology to move or tilt. They are typically made of silicon or other semiconductor materials and can be controlled using electrostatic forces, magnetic fields, or other means. MEMS mirrors offer several advantages over traditional mirrors, including small size, low power consumption, and high precision.

How MEMS Mirrors Work

Our MEMS mirrors work by using tiny electrodes to create electrostatic forces that can tilt or move the mirror. The amount of tilt or movement is proportional to the voltage applied to the electrodes. This allows our MEMS mirrors to be controlled very precisely.

Advantages of MEMS Mirrors

MEMS mirrors have several advantages over traditional mirrors, including:

- Small size: our MEMS mirrors are very small, which makes them ideal for use in applications where space is limited.

- Low power consumption: our MEMS mirrors consume very little power, which makes them ideal for use in battery-powered devices.

- High precision: our MEMS mirrors can be controlled very precisely, which makes them ideal for applications that require high accuracy.

- Versatility: our MEMS mirrors can be used to reflect, redirect, or block light.

Applications of MEMS Mirrors

MEMS mirrors are used in a wide variety of applications, including:

- Telecommunications and Satelites: our MEMS mirrors are used in telecommunications equipment to route light beams to different destinations.

- Laser printing: our MEMS mirrors are used in laser printers to direct the laser beam onto the paper.

- Display technology: our MEMS mirrors are used in some projectors and televisions to create images.